Top Bar Hive Products

Cut Comb Honey from Top-Bar Hives

The premium top-bar hive product is probably cut comb honey sold in clear clamshell containers. I have seen cut comb honey selling for around $20 per pound, as shown in a few pictures below. Beekeepers should get a higher price for this honey product because they are selling the new comb too. Cut comb honey production eliminates two big costs: the honey extractor and jars. Below I am harvesting honeycombs, from my five-foot top-bar hive. My top-bar hive book gives the logistical details from harvesting to packaging.

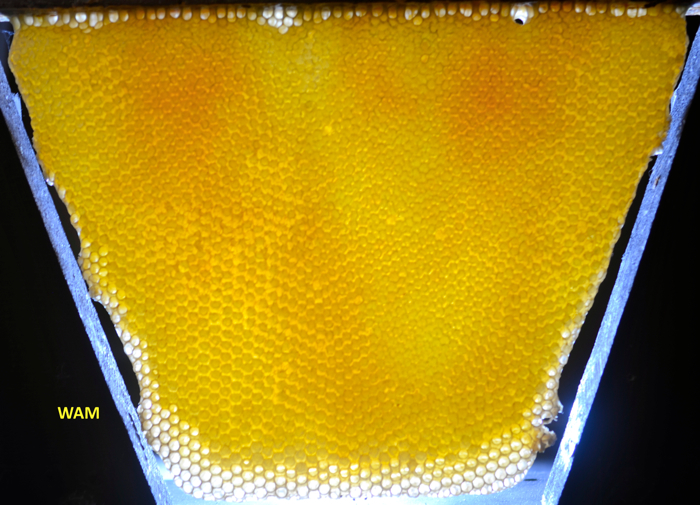

Here is a typical top-bar honeycomb, back lit to show its true beauty. Notice in both photographs, above and below, the bees built the honeycombs straight to their top bars. I do not have problems with crooked combs.

Below are cut combs in their clamshells: the left one in regular light and the right one back lit. People find back lit honeycomb quite compelling and it makes wonderful displays.

Below is an example of cut comb honey from a kitchen set up. The pieces weigh a little less than a pound. They are draining on a cookie rack and into a cookie pan. Then they go in the clamshells as above. The scrap pieces go together, several in a clamshell as shown below to the right. The beekeeper sells her/his crop by weight. So the scraps in the clamshells just get weighed out like the larger pieces. One top-bar beekeeper told me she gets $1.25 for her SCRAP cut comb honey. She sells it in the little round condiment cups like you get at restaurants. One needs to be creative.

And finally here is some cut comb honey we saw for sale at a farmers’ market in Pennsylvania. The price was $11.99 for 10 ounces. Considering the low start-up cost for top-bar hives by building them yourself, this kind of revenue is quite good. But having the hive, the woodenware only, is not enough. You need know how to care for, that is, manage, the bees in this horizontal hive design, which is why the management chapter of my book is so long and detailed.

Liquid Honey from Top-Bar Hives

Local honey sells for $10 – $15 per pound. Processing liquid honey from top-bar hives simply requires draining the honey from crushed comb. The best combs are newly built combs of pure wax, never used for brood rearing. I call this liquid honey instead of extracted honey. With top-bar beekeeping I have not yet seen an extractor that is efficient and meets my cleanliness standards. Top-bar beekeepers have devised numerous methods to separate the honey and wax. Remember, surfaces (buckets, strainers, etc.) coming in contact with the honey must be approved for contact with food. For example, stainless steel and food-approved plastics are fine.

Below are honeys of different colors. The honey jar to the far left has a light amber color from “wildflowers” seen in natural daylight. The two jars to the right are in my polariscope, used to see crystals in honey (a natural crystal-growth process), and for detecting contaminants in honey. The middle jar contains a slew of fine crystals giving the honey a cloudy glow. The far right jar has a virtually clear honey, which shows clear in the polariscope. The polariscope eliminated the background glare (when configured correctly). The crystals became visible in this honey. A layer of large crystals was growing across the bottom of the jar. A few crystal splotches were near the top of the jar. Suspended and scattered throughout the honey were tiny crystals, which were probably growing too. All revealed by the polariscope. The crystals shown by the polariscope can be quite stunning as shown on my web page on a polariscope.

For an example of how much honey top bar hive colonies can produce, chick here.

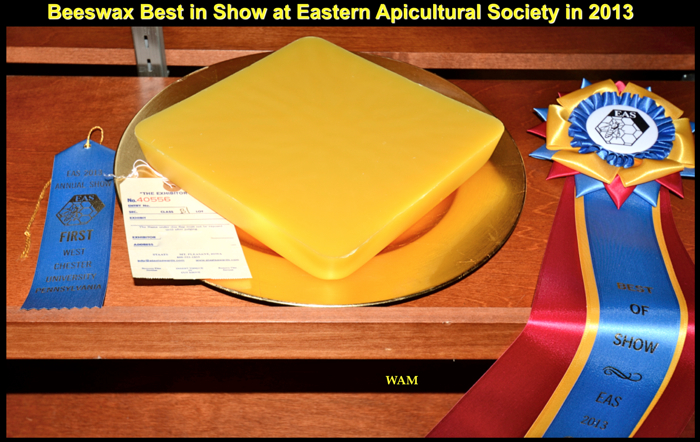

Beeswax Production from Top-Bar Hives

For some top-bar beekeepers and others, wax production is their primary goal, even over honey production. They use the beeswax for candles, all kinds of figurines, soaps, and lotions.

A large amount of wax results from crushing combs for liquid honey. I have two large solar melters, for light and dark combs, for melting combs into 25-pound wax blocks. Most beekeepers store their wax as blocks. Below is a collection of wax products that I have seen at various beekeeping meetings from top-bar and frame-hive beekeepers.

Notice the rolled foundation candles above. Below is a creative addition to the rolled foundation candles. The bees have partly build out the cells on the candles.

Pollen Production from Top-Bar Hives

Some beekeepers sell pollen trapped from their colonies. The pollen can be trapped when it is super abundant, stored properly to protect it from pests, and it can be fed back to the bees during times of protein famine.

Since the late 1980’s I have been trapping pollen with my top-bar hives.

Below is my original pollen trap, which plugs on to the front of a top-bar hive.

The pollen pellet colors in the drawer change from day to day, and even within a day. As an example, to the right is a drawer of pollen collected from one summer morning.

Watching the pollen drawer keeps you closely connected with changes in your bees and changes in the bloom of pollen plants, at least the ones the bees are working.

Renting Top-Bar Hives for Crop Pollination

I specialized my 200 top-bar hives for a mobile operation doing crop pollination. The book has a chapter telling how I did it. On a smaller scale, one can rent a few hives as shown below. The first shows six top-bar hives pollinating 12 acres of pumpkins off in the distance (the upper corner of the right picture). The farmer supplied the pallets.

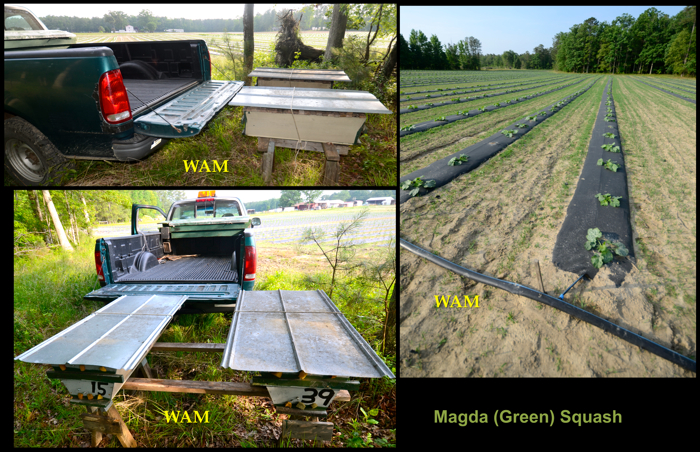

Below is one of my top-bar hives pollinating several acres of Magda (Green) squash. I ran out of two-foot long top-bar hives, my standard pollinating hive size. The hive below S-2 is a three-foot hive with a screen floor, not needed that summer for my experiments (note the extra thick bottom board). To the right is a long row of green squash.

Below I am unloading a pair of three-foot top-bar hives in a shady spot near the edge of a new field of green squash. The hives are heavy. I just slip them off the tailgate of the truck onto the hive stand. In the two left photographs, the squash field is in the distance, out of the shade. In the right photograph, the hives are at the other end of the long rows under the trees.

When needed, I can move five-foot hives for pollination, if I run out out two- and three-foot long hives. A five-foot long top-bar hive can weigh almost 250 pounds. But like I said in the book ALL my top-bar hives are very mobile – easy to move, no problem. Even the five-footers.

In the upper left photo, I am in the apiary sliding the hives onto the truck bed (standing on the cab shooting down). In the upper right photo, I am unloading a heavy five-foot hive. In the lower photo, I have finished unloading five-foot hives for green squash pollination. Three five-foot hives are in the foreground.

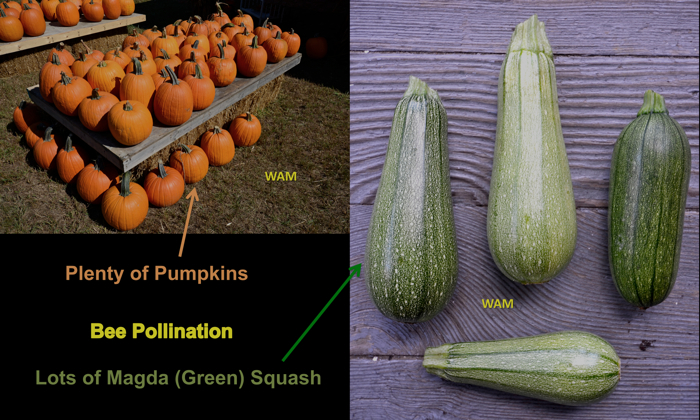

Here are the results of proper pollination, plenty of Pumpkins and Magda squash. Besides honey bees, bumble bees and squash bees can also be found in their flowers.

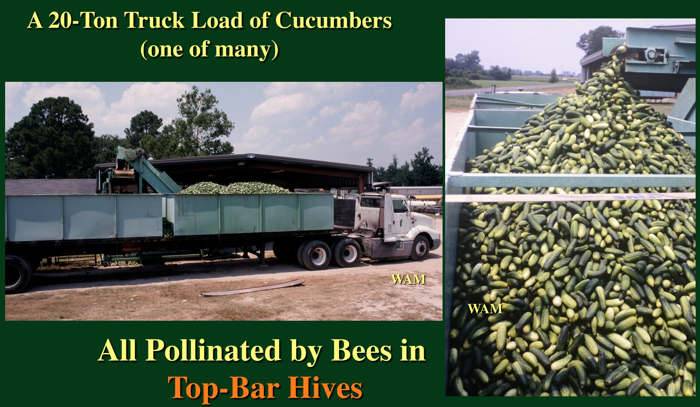

When I rented 200 top-bar hives, mostly for cucumber pollination on large farms in eastern North Carolina, below was a common sight at the grading station close by where my bees did their pollination. After an inspection and getting sorted by size, the cucumbers left for the pickling plants, in 20-ton truckloads.

Rearing Honey Bee Queens with Top-Bar Hives

Queens cost around $20 now. Locally produced queens from varroa tolerant/resistant stock with adaptation to local conditions are in demand by beekeepers. I use standard accepted queen rearing practices, just in top-bar hive equipment. My book has a chapter devoted to queen production with top-bar hives. Some of my queen bees are below.

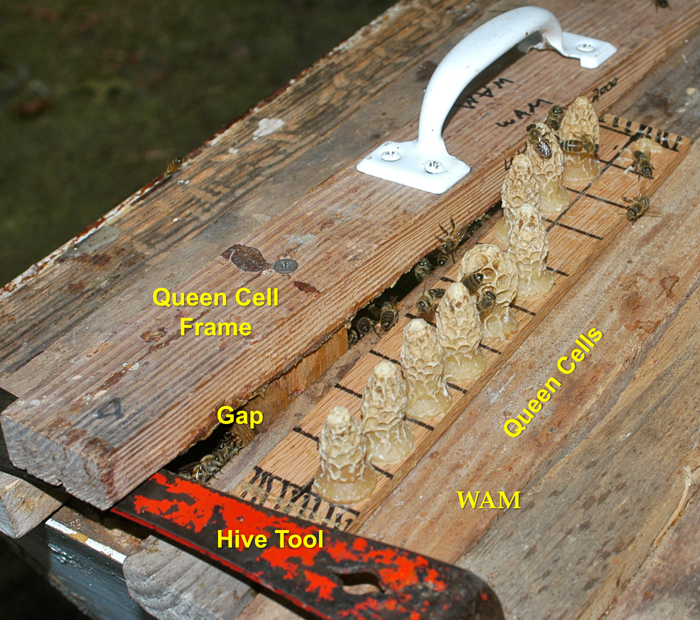

I found top-bar hives to be efficient for queen cell production, given the frequent cell bar manipulations. Below is a special queen cell frame for holding the queen cells on three cell bars.

This queen cell frame can hold a maximum of 60 cells for starting them in a swarm box as shown below.

After the bees in the swarm box start the cells, I put groups of 20 queen cells into the cell finishing top-bar hives. Three of these cell finisher colonies are below. To move the queen cell bars around, I just pull up on the top white handle (marked by the white arrows, below). That lifts the frame holding the queen cells. In a few seconds, I am right at the queen cells with a minimum disturbance to the nurse bees. In this photograph, taken during the summer, the afternoons are hot. The nurse bees might cluster on the outside of the hive ignoring the queen cells. The yellow arrows mark the double screen ventilators. The yellow oval shows the plywood cover, which is on all the hives. Under the covers are my open-top syrup feeders. The hives are under a shed roof, eliminating their metal covers, making them even easier to open.

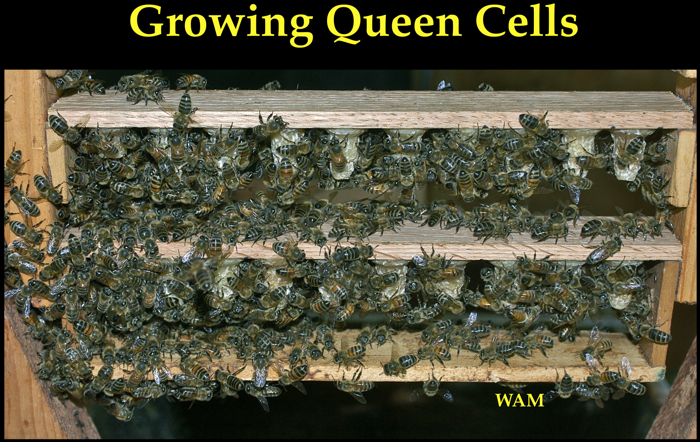

Below are queen cells from a cell builder colony covered in nurse bees. They feed the queen larvae lavish amounts of royal jelly. I just grafted a single row of queen cells in this batch, ten on each bar.

To remove some queen cells with barely disturbing the nurse bees, I lift up the queen cell frame by the handle and remove a cell bar. Then I rest the frame on the hive tool (red) as shown, which forms a gap leading directly back to the other queen cells. Next I put the cell bar beside the gap as shown. (Mature queen cells can be turned upside down.) The nurse bees will scurry back in the hive through the gap with just a little coaxing. They run right back to the other queen cells.

Below I am collecting up sealed queen cells from the cell builders for a trip to the mating apiary. I put the queen cells in a special box with a sponge cut in grooves to hold the cells.

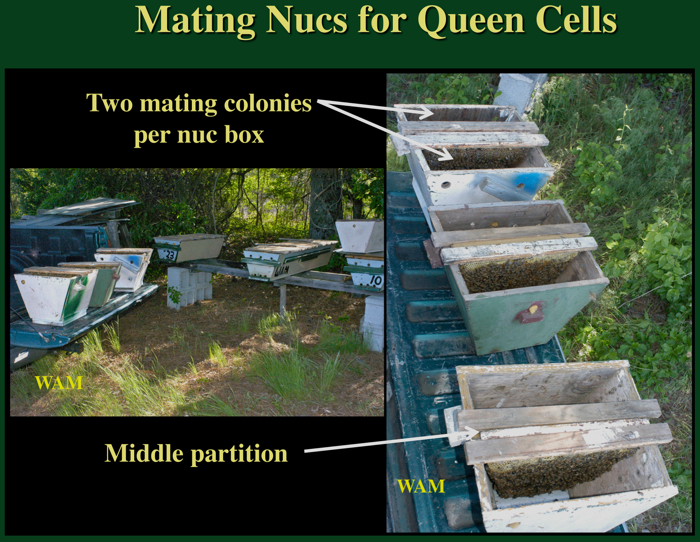

Below I am making up mating nucs, two little colonies in each box. I will attach queen cells to their combs (one per colony), load the hives on the truck, and haul them to a mating apiary. When attached properly, the queen cells will not fall out of the combs.

Package Bees from Top-Bar Hives

A three-pound package costs about $100. Once a top-bar hive beekeeper has many hives, a surplus of bees can occur. I have sold up to 70 booster three-pound packages in a season, which were queenless and needed no syrup can because they were fed from the outside (of the package) and meant to be hived quickly.

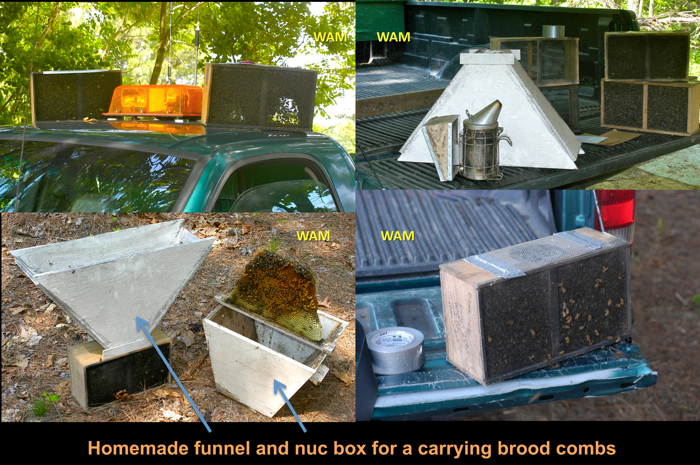

In the beginning, use a scale to figure out when the package has three pounds, although that is the slow way. Below, the nuc box holds brood combs from strong colonies ready for shaking through the funnel. The brood combs are strong and do not break when shaking off the bees, as explained in my top-bar hive book.

Below are photographs of shaking bee packages from my top-bar hive apiaries.

As this page shows, there are several ways to generate revenue from keeping bees in top-bar hives, to go along with the enjoyment of keeping bees. My top-bar hive book shows you how to get started with the hives, building the hives, putting in packages, producing honey, and proceeding to the more advanced topics like queen rearing. Click here to return to the book-ordering main page.

Please consider donating to support these pages by clicking on the button below and entering credit card or debit card information. Paypal handles all the security. Thank you.