“Green” Top Bar Hives

On this page, I show my top-bar hives built in sustainable ways to eliminate buying new wide boards for hive construction. With the typical top-bar hive construction, the sides and ends are made from wide boards (called 12-inch boards), which are fairly expensive. Eliminating these wide boards cuts hive costs greatly and reduces (a bit) the demand for logging. I do not paint these hives either, another cost reduction, which saves time too. This results in more environmentally friendly top-bar hives. (Even when using wide boards, my hives last over 20 years mainly because of my metal covers. The durability of these hives lowers the demand for wood and of course lowers the overall cost of the hive.)

The philosophy with these “green” top-bar hives is to build top-bar hives from locally available materials (the technical construction details for the hives below are given in Chapter 10 of my top-bar hive beekeeping book, which can be ordered from the Welcome page).

Sunflower Stalk Top-Bar Hives

Below is an innovative hive made from sunflower stalks and scrap two-by-fours. One could grow sunflowers, enjoy the beautiful flowers, and harvest the seeds (either as food for people or wildlife, or by pressing the seeds for cooking oil as they do in some farming operations). The bees provide the pollination for the seed production. The sunflowers provide nectar for the bees. The beekeeper could also produce sunflower honey if the sunflower fields are large enough. Now as an added benefit, the sunflowers provide hive construction material: plant stalks for the sides and floors of the hives. The two-by-fours and other wood scraps come from discarded lumber. Even the top bars can be cut from scrap wood as many of mine were.

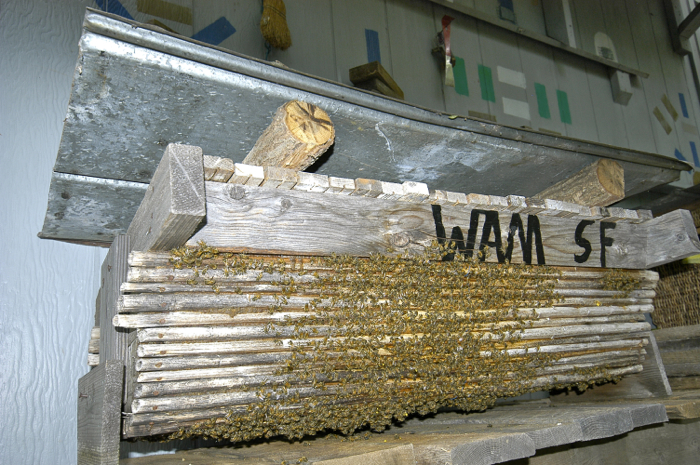

In addition, the five-groove roofing tin for the top of the hive came from a dismantled barn. I nailed the roofing tin to the cut branches, which are heavy slow-growth oak. All together the metal and wood make a sturdy hive top for essentially no cost. Still, the top should be tied or weighted down as explained in my book. The hive shown here is three feet long. Sunflower stalks four or five feet long would give more honey capacity for the hive. (The SF on the hive stands for sunflower.)

I just let the bees have their entrance through a crack between the branches. The bees also have clustering space under the hive. As I explain in the book, the bees spread a thin layer of propolis around the entrance, helping to seal and waterproof the hive. This behavior helps to reduce painting top-bar hives made from wide boards. For hives made from plant stalks (with multiple side entrances), like sunflower and weed stalks (even the woven caning material shown below), this exterior propolis seals and protects the hive. It is possible to get the bees to seal up most of the hive exterior with propolis so I do not paint these hives (see book for details).

The bees winter well in the hive in the relatively mild winters of eastern Virginia, although we have long cold durations without bee flight. In more northern locations, I suppose the bees would need more hive protection with apiary sites chosen carefully. In hot locations, I recommend shaded apiaries (all my apiaries are shaded).

Weed Stalk Top-Bar Hives

Someone needs to cultivate sunflowers. What if the stalks for the top-bar hives “grew” wild? And you just had to “pick” them? The lower left picture shows the weeds ready to pull out of the ground after their seeds have floated away. I do not want my harvest to harm the plant’s reproduction. I do not know the plant’s name, but it is a common weed in my area. I collect them in late summer to fall. The picture on the right shows some weed stalks in the pickup truck with the branching tops and roots still attached. Beside these is a pile of stalks, their branch tops and roots cut away, leaving the straightest and thickest part of the stalks. When dried, the weed stalks are very tough, excellent for making top-bar hives.

Below is a hive made from these weed stalks. It is a two-foot hive, which could be employed for pollination (Chapter 7) or queen bee production (Chapter 8). I am working on building longer hives from these weed stalks too. Note that the hive entrances are in the lower corners. (The left entrance is blocked by a sponge, while the one on the right is open.)

Woven Cane Top-Bar Hives

Hive material can pop up almost anywhere. One day I was at the flea market and saw a roll of woven cane material. To me it was a roll of top-bar hives. So I bought it. The roll of woven cane was lot cheaper than buying boards for the sides and floors and lighter in weight too. For the hive below, the entrance is near the upper left corner.

Scrap Wood Top-Bar Hives

Here is a scrap wood top-bar hive still made without wide boards, just old narrow boards of different widths and two-by-fours. Such a top-bar hive could of course be longer for honey production.

Here is a front view of the hive showing the top bars. I left a crack at the bottom edge for an entrance. I don’t have a standard entrance placement on these hives like my other hives (with the six entrance holes on the ends). On future hive designs with these materials, I plan to have the six-entrance holes on the ends of the hives because it makes opening them so much easier.

Here is an important point: The four hives made from sunflowers, weed stalks, caning material, and scrap wood all have the same cross section so all their top-bar combs are still interchangeable for efficient colony management (for example, equalizing colonies in the spring to share honey to save a starving colony, the management techniques detailed in Chapter 5).

Now people with very limited money can build top-bar hives for very little cost. The beekeeper can still manage the bees in these hives to keep them healthy and productive like any other beekeeper (with frame hives) because these “green” hives have interchangeable combs, the core foundation of modern bee management. Said another way, the hives below may look different from the outside, but inside the combs are the same size.

Beekeeping need not be expensive, but one still needs to learn bee management to maintain healthy productive colonies. My book on top-bar hive beekeeping has an extensive chapter on bee management (Chapter 5), since so little has been written about that subject. Chapter 5 alone is about 100 pages with about 96 detailed photographs. The entire book is 421 pages with some 350 photographs. The book can be ordered from the Welcome page.

“Green” Hive Apiary

I’ll add more pictures later of upcoming green hives. To learn a complete system of beekeeping for top-bar hive beekeeping, please go back to the Welcome page to order the book. I hope you enjoyed looking over the pictures. Kind Regards, Dr. W. A. Mangum/WAM.

Please consider donating to help support these pages by clicking on the button below and entering your credit/debit card information. All the security is done by Paypal. Thank you.